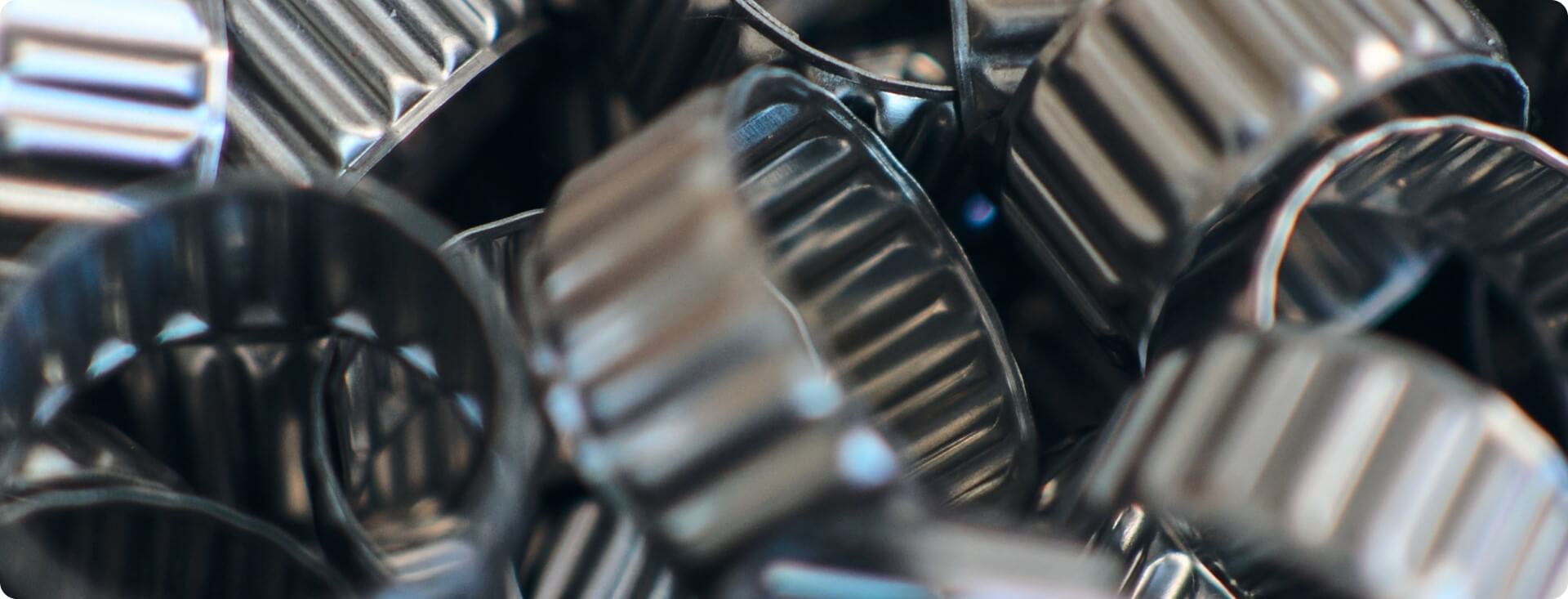

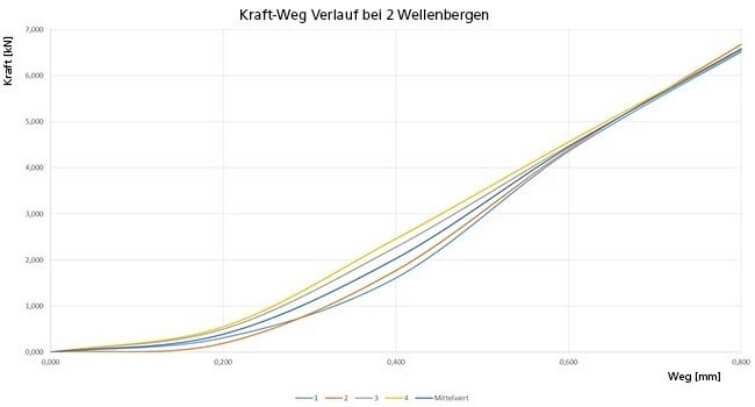

The tolerance sleeve is a tried and tested connecting element. The sheet metal sleeve, in which corrugations are embossed, presses against the parts to be joined. The resulting spring-elastic deformation represents a calculable, force-fit connection. Above all, the given torque transmission is a central part of the calculation of the tolerance sleeve.

As the correct design of the tolerance sleeve and the requirements placed on it are very complex, we will be happy to support you. For simple applications, such as the mounting of ball bearings, the calculation of the tolerance sleeve can be a simpler undertaking. However, as soon as several components are involved, these must also be designed appropriately. Our experienced design engineers will support you in the design of the tolerance sleeve – even at an early stage of development.

For standard applications, such as rolling bearing attachment or, for example, pulley attachment (torque transmission), we have listed the required installation diameters in our “Tolerance Sleeves” catalog for you. There you will also find a simple calculation formula for roughly estimating the assembly force and the axial seating force. For more special applications, such as larger tolerances to be bridged, different thermal expansions of the materials or special requirements for the seating / assembly force, we will be happy to support you in the design of the tolerance sleeve or another suitable connection solution and accompany you in the test phase as well as in the design of the tolerance sleeve.