Torque transmission with tolerance sleeves: applications and advantages

Tolerance sleeves are versatile aids used in both individual and series production – whether in mechanical engineering, conveyor technology, motor vehicles, ventilation and air conditioning systems, or medical technology. They reduce oscillations and vibrations, compensate for alignment errors and center offset, and bridge large tolerances of connecting parts. They are most often used as connecting elements, slip or overload clutches, for adjustment or positioning (friction elements), and for torque transmission. We will take a closer look at the latter function in this article.

Common components for torque transmission: shaft-hub connections

In friction-locked shaft-hub connections, one or more components are clamped against each other between the shaft and the hub. They enable the transmission of torsional and bending moments as well as axial and transverse forces, making them a central element of many drive systems. Tolerance sleeves, for example, are very well suited as a shaft-hub connection. Similar to parallel keys, wedges, or splines, they can reliably transmit torques. They connect components without play, compensate for manufacturing tolerances, and thus ensure a robust, economical, and, at the same time, easy-to-assemble solution.

Practical applications

- Positive and non-positive locking of the stator in electric motors

In modern electric drive manufacturing, tolerance sleeves are an efficient alternative to gluing. Instead of time-consuming application, curing, and post-processing, simple pressing in is sufficient – immediately, reproducibly, and without waiting time.

Practical advantages:

- Larger manufacturing tolerances due to appropriate tolerance design

- Lower costs and higher process reliability

- Reliable compensation of thermal expansion differences

- Stable seating of the stator even with changing temperatures

In addition to stators, rotors can also be securely attached to drive shafts. Especially in dynamic applications with high torques, the press connection impresses with its stability, economy, and safety. The elimination of solvent-based adhesives also improves environmental and occupational safety.

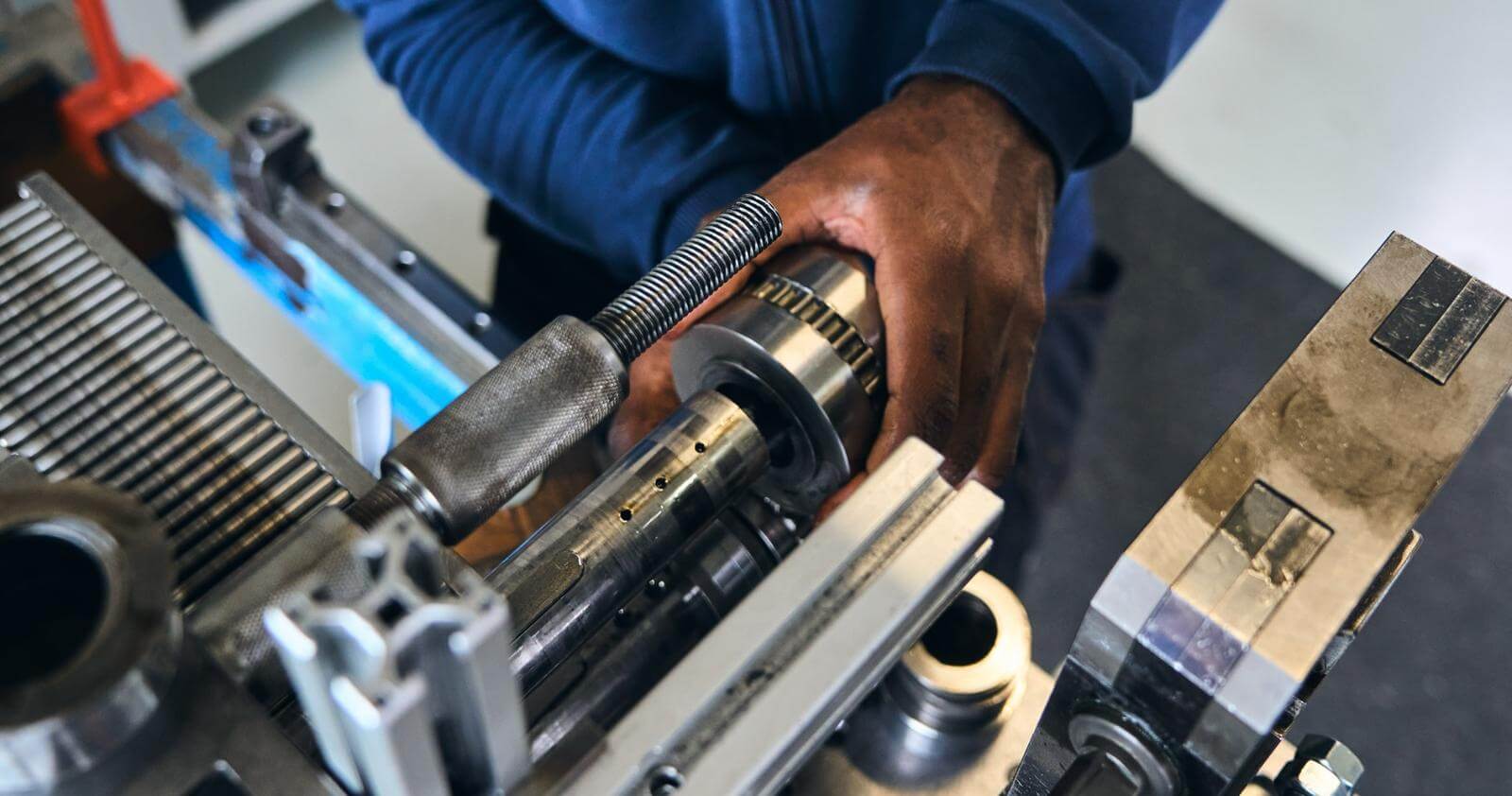

- Conveyor belts

When designing conveyor belts, the challenge is to implement a connection between a drawn steel tube and a shaft for the driven conveyor roller that is both cost-effective and robust. The use of an AN tolerance sleeve is ideal for this purpose. This is inserted into a recess in the conveyor roller and pressed into position over the shaft.

Practical advantages:

- The position of the conveyor roller on the shaft can be changed subsequently, for example for sensors or attachments during commissioning

- No reworking of the connecting parts required

- Compensation of frequently occurring thermal expansion

- Very easy assembly

The result is a reliable, flexible, and economical connection solution for roller conveyors.

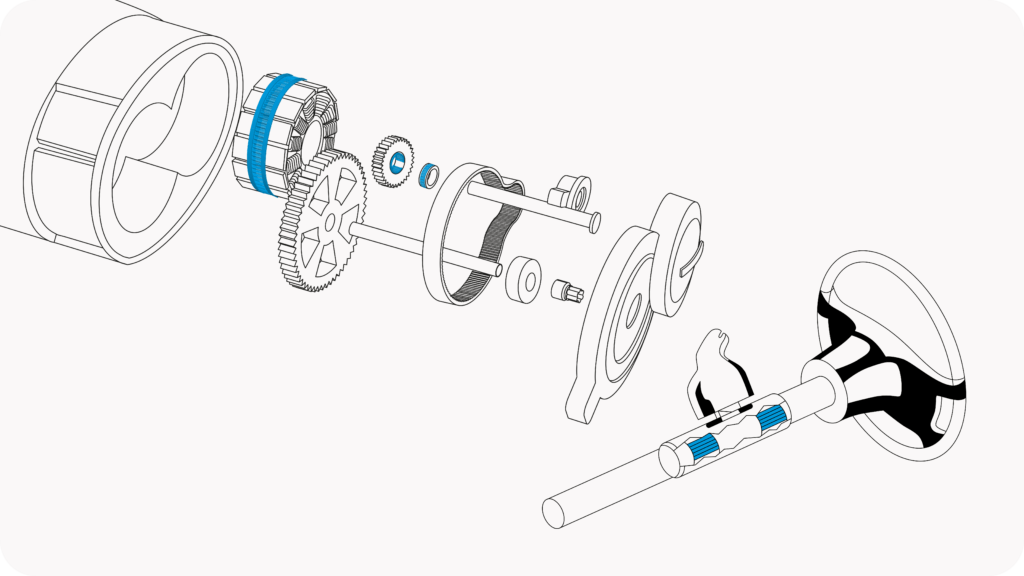

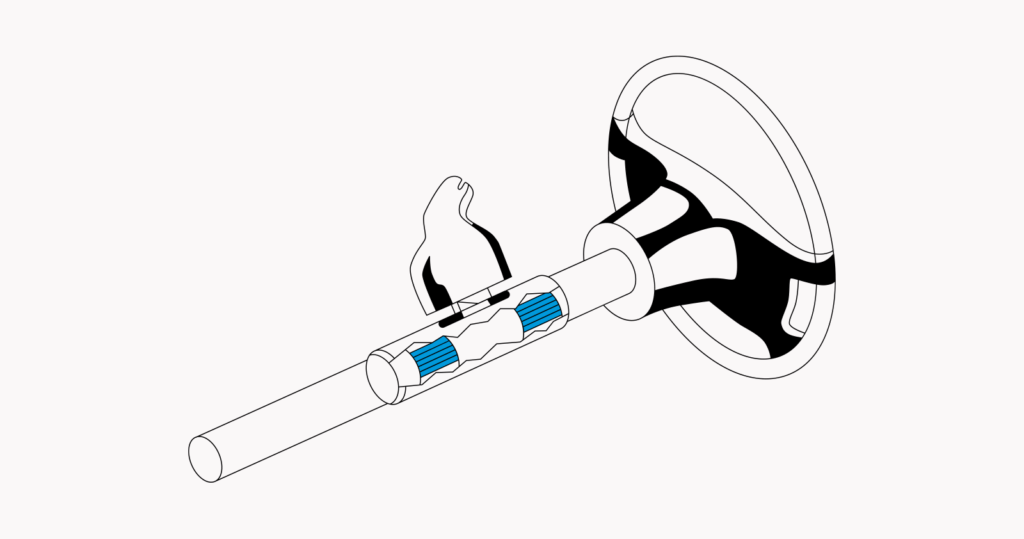

- Slip clutch in the steering system

Tolerance sleeves can also be used as a slip clutch, for example as an anti-theft device in the steering system of a vehicle. If the steering wheel is turned jerkily and with a lot of force in one direction, the locking bolt breaks off and the steering spindle slips through. In addition, the torque is too high to steer the vehicle.

Conclusion: Tolerance sleeves are a versatile and economical solution for the safe transmission of torques, for fixing components, and for compensating for manufacturing tolerances. Their simple assembly, high reliability, and flexibility in design make them an ideal element in numerous industrial applications.

If you are looking for a connection solution for your project, we would be happy to support you from design to the test phase.

info@tretter.ch