The two dimensions of innovation: Engineering and production

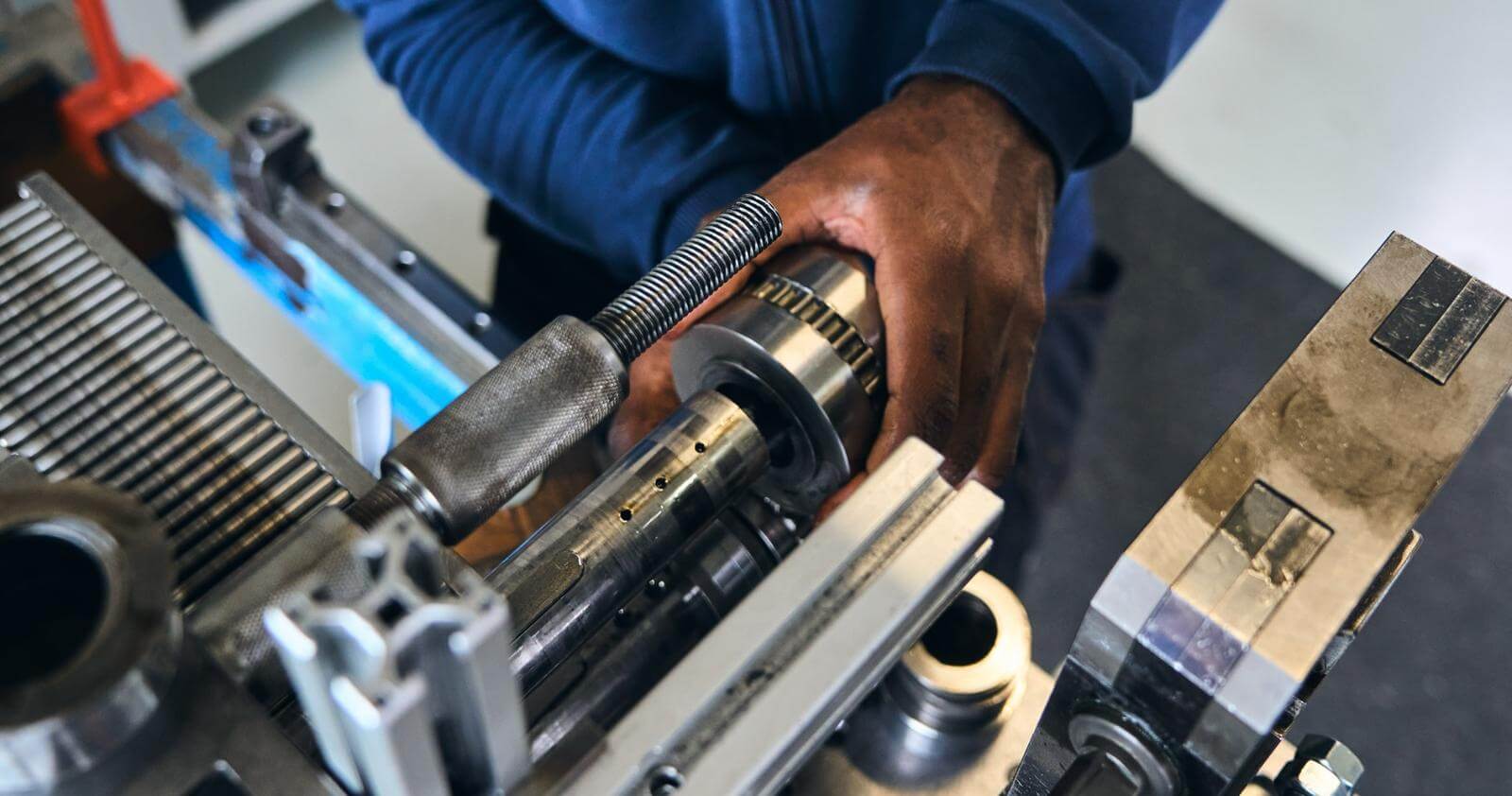

Innovation has two dimensions for us: engineering and production. On the one hand, we work with our customers to develop individual applications and implement tailor-made special solutions. On the other hand, we continuously invest in the further development of our own machine portfolio – an area that has improved significantly in the last ten to 15 years. Most recently, we invested in a new cutting system to offer our customers even more flexibility, capacity and quality. The new machine enables us to implement larger formats and more complex orders for which we previously lacked the capabilities. Through such investments, we enable new orders, secure jobs and create modern working conditions.

This dual approach creates new manufacturing opportunities, raises our quality standards and enables us to react flexibly and precisely to customer needs. For us, innovation therefore means not only technological progress, but also partnership and long-term competitiveness. Because technical innovations are not created by machines alone, but by people: expertise, experience and the willingness to break new ground are the basis for every advance. The focus is on our team with its expertise, which translates complex requirements into practical solutions.

Engineers with foresight

Before a component takes shape in production, the work begins on the screen. Our engineers develop and simulate digital models, test functions and optimize processes. With modern software and sound know-how, we create solutions that guarantee maximum precision and reliability in practice.

Production as a source of innovation

Production shows what makes Dr. TRETTER special: experience, commitment and ingenuity. Our colleagues are constantly developing machines, solving complex challenges and always surprising with creative approaches. This innovative strength from within the company makes a decisive contribution to ensuring that we not only satisfy our customers, but also inspire them time and again.

What does that mean in practice?

Using the following examples, we will show how we deal with specific questions from our customers:

Requirement: Feasibility of a small torque guide for a new automation cell

Solution: After numerous discussions, team meetings and visits, the customer placed the first order for three units half a year later. After successful tests, the customer regularly ordered one to four additional torque guides of this type. This year, the first series of over 20 units was started.

Requirement: Linear guides, ball screws and bearing units for the prototype of a feeding system in mechanical engineering

Solution: Marketing the premium versions proved difficult because the components were expensive and not tailored to the target group. In a personal discussion on site, we adapted the requirements and were able to offer variants that reduced the parts costs by around 50%. This gave the customer a clear competitive advantage and the system is now being produced in small series.

Requirement: Replacement for ball screw for storage barrels

Solution: During a test run, the customer noticed that the spindles of barrels with highly sensitive cargo were damaged. He needed a replacement at short notice. We reacted spontaneously, measured the old spindles and, thanks to readily available material and our manufacturing expertise, were able to deliver suitable replacement spindles the very next day, thus ensuring the safe transport of the barrels.

These examples show that innovation at Dr. TRETTER always arises when experience, team spirit and customer proximity come together. Our goal is to solve technical challenges together with our customers and derive sustainable improvements for products and processes.

The combination of state-of-the-art manufacturing technology, in-depth engineering knowledge and precise Swiss quality forms the basis for realizing individual and efficient solutions in the future.

Would you like to find out more about how we can implement innovation in your project? Please contact us: info@tretter.ch.