Strong customer and supplier relationships for sustainable success

Collaboration and cooperation are important cornerstones for progress in production. It is not without reason that the saying goes: “Four eyes see more than two”, be it within a team, between departments or with external partner companies. Partnerships are a decisive factor in driving technological progress, improving supply chain efficiency and overcoming economic challenges.

The strength and quality of relationships with partner companies can play a crucial role in a company’s success. They affect many areas, from supply chain reliability and cost management to product quality. Effective management of customer and supplier relationships is a top priority for us in order to master the challenges in manufacturing and ensure a smooth production process.

We see ourselves as more than just a supplier and manufacturer. As engineers, we can offer new technologies, materials and processes that give our partner companies a competitive advantage. By pooling our collective expertise, we can continuously improve products and processes, thereby fostering innovation and growth.

Trust and open communication are the best foundations for successful business relationships. Our experience shows that shared goals can only be optimally achieved with transparency, reliability and mutual commitment. Through regular communication, we ensure that both sides are on the same page and that any problems can be addressed promptly.

Of course, this costs time and effort. However, this investment in building and maintaining strong partnerships is not only a strategic advantage, but a necessity in today’s fast-paced and demanding market.

Practical examples

A customer was looking for linear guides, ball screws and bearing units for the prototype of a feeding system for mechanical engineering. He opted for the premium versions in each case. However, marketing proved difficult as the components were expensive and not geared to the target group. Through a personal discussion on site, we were able to adapt the requirements and offer more cost-effective variants, which reduced the parts costs by 50%. This gave the customer a competitive advantage. The system is now being produced in small series.

In January 2022, we received an enquiry regarding the feasibility of a small torque guide for a new automation cell. After many discussions, team meetings and visits, the first order for 3 units was placed in June 2022. Following successful tests, 1 to 4 additional torque guides of this type were regularly ordered. The first series of at least 20 units is scheduled to begin this year.

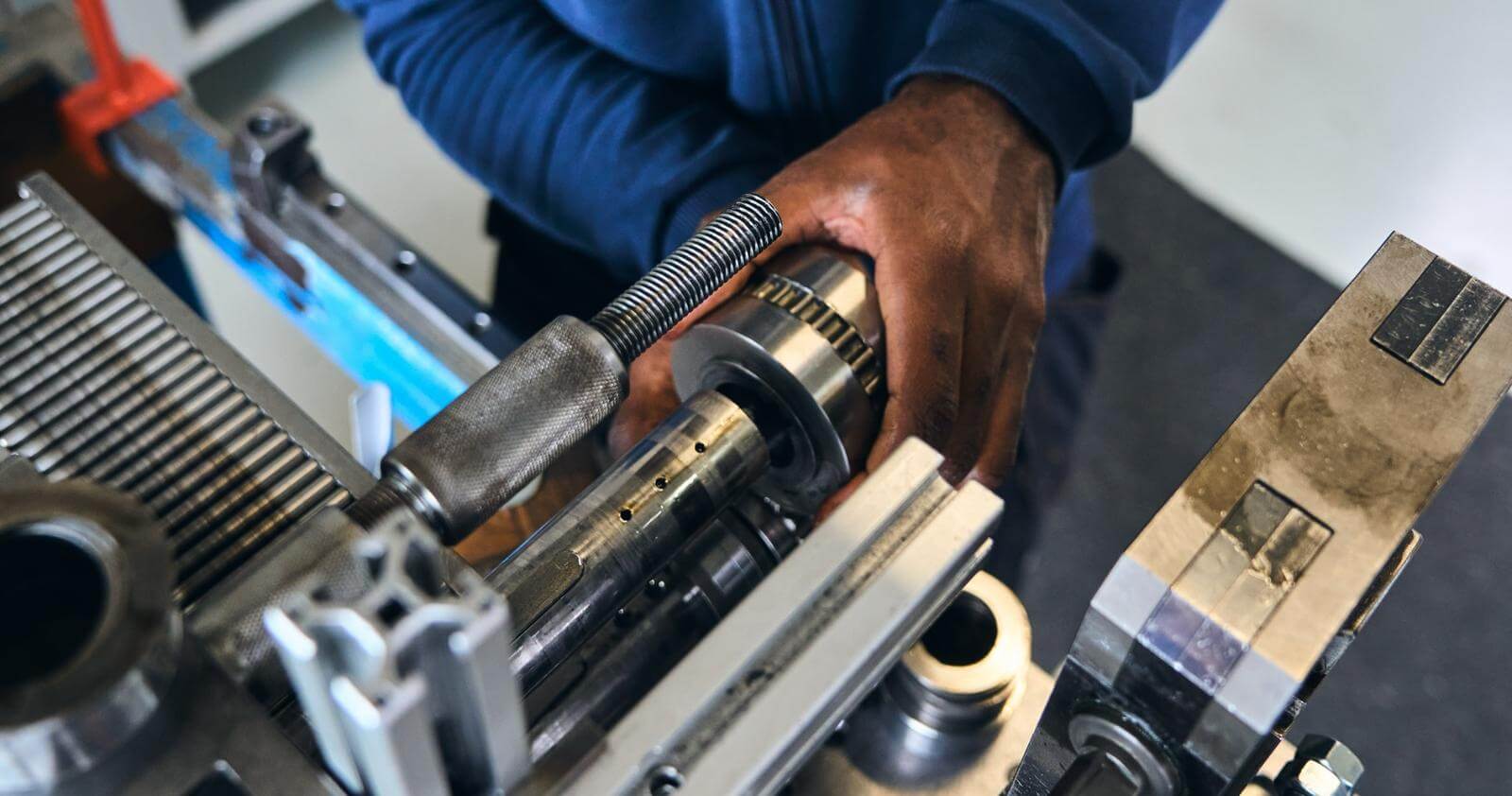

In October 2022, we received an enquiry for linear axes via our website for a redesign of existing systems for the printing industry. We provided a quotation and CAD data, which were immediately incorporated into the design. In January 2023, we received the first orders for linear axes, followed by ball bushing units in February. The products have been running in small series since mid-2024.

In April 2024, a customer from the woodworking machinery sector enquired about track roller linear guides for a new generation of machines. We then implemented a test setup, which is still undergoing continuous testing. In the meantime, we have been able to supply various guide parts, provide various technical consultations and offer further products for sub-projects.

If you want the best products, rely on strong, cooperative partnerships. The benefits will pay off and make your company more efficient, innovative and successful. As a specialist for tolerance sleeves and linear guides, we develop tailor-made solutions for your individual needs. In doing so, we rely on years of experience and a genuine dialogue to find the right solution. Contact us!