Leadscrews: Precision drive elements for linear movements

Leadscrews are indispensable machine elements when it comes to converting a rotary motion into a precise linear motion. They are used in numerous industries, including mechanical engineering, measurement and testing technology, the automotive supply industry, automation and conveyor technology, and woodworking. The two most common types are ball screws and trapezoidal screws.

Ball screws – high efficiency and precise positioning

With ball screws, the power is transmitted via small, circulating balls between the spindle and the nut. This design ensures a very high degree of efficiency, minimal friction losses and precise positioning. Ball screws are available in rolled, swirled or ground versions. Ground versions offer the highest accuracy, a zero-backlash or low-backlash design (e.g. 0.005 mm) and particularly low noise emissions.

Advantages of ball screws:

- High efficiency and exact power transmission

- Zero-backlash or low-backlash versions available

- Low noise emissions thanks to high-quality surfaces

- Standard versions available from stock or individually according to drawing

- Ideal for applications in linear guides

Trapezoidal screws – robust and cost-efficient solution

Trapezoidal screws work on the principle of sliding friction. They are an inexpensive alternative to ball screws and, in certain designs (single-start, helix angle < 4°), offer self-locking, an advantage for lifting or clamping devices. In addition, they are also available in corrosion-resistant materials that are resistant to salt water and acids.

Advantages of trapezoidal screws:

- Attractive price-performance ratio

- Self-locking in certain versions

- High availability in stainless steel

- Low maintenance

- Versatile in many industries

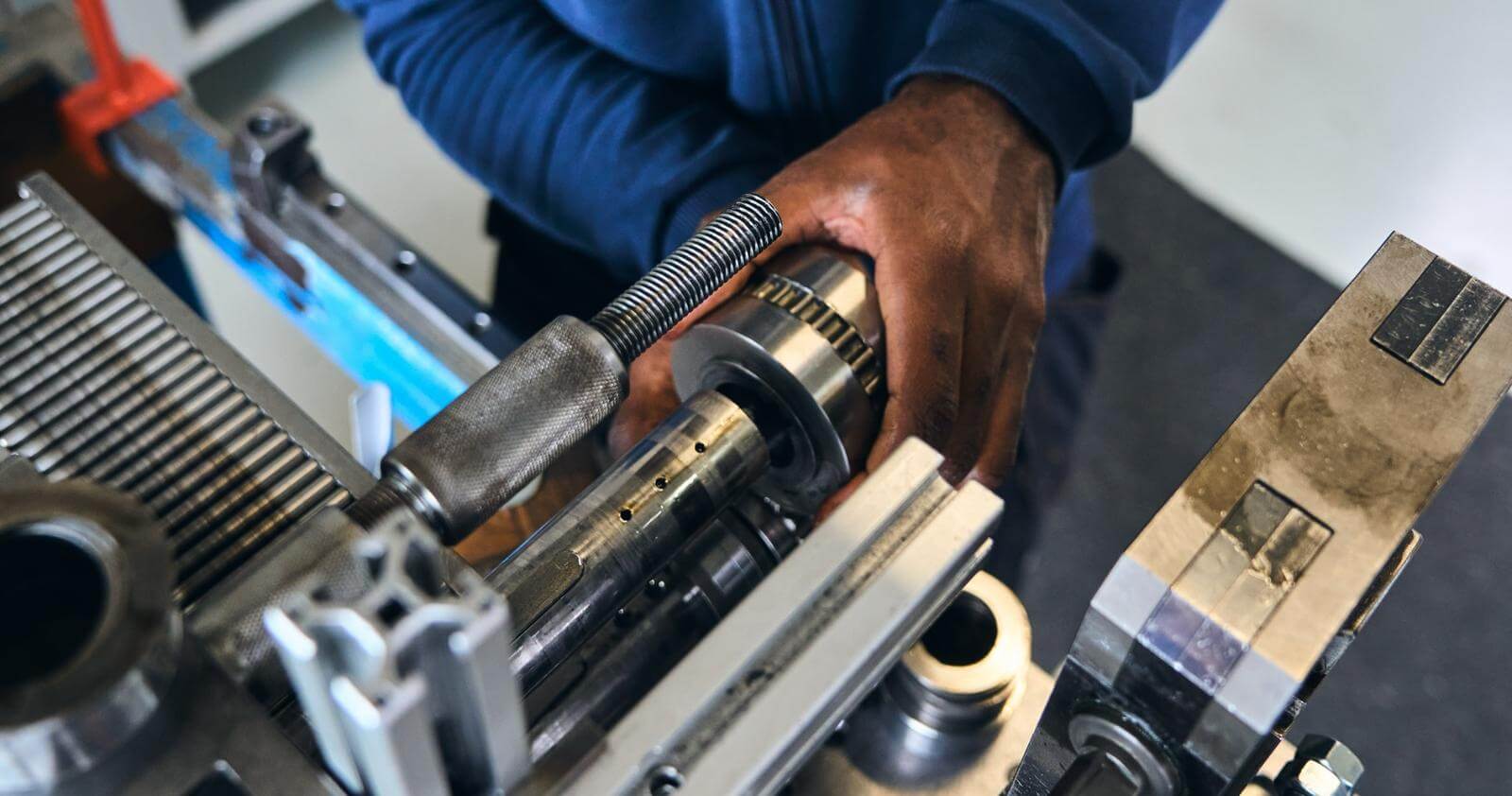

Precision from Dr. TRETTER AG manufacturing

We manufacture leadscrews with nuts in the highest quality, from individual pieces to small and medium-sized series. Our modern production facilities enable various thread sizes, pitches and lengths, also in rust-resistant designs. The end machining is carried out exactly according to customer drawings. By using precision-ground spindle materials, we achieve excellent shape and position tolerances in accordance with DIN 69051. Each manufacturing step is checked and documented by trained specialists.

Whether ball screws or trapezoidal screws – with us you receive high-quality standard products and tailor-made solutions. Together with you, we will find the right spindle for your application.