Fits and Tolerances – Between Theory and Industrial Reality

In industrial manufacturing, components cannot be produced with absolute dimensional accuracy. Even modern machines and automated processes cannot completely eliminate influences such as tool wear, temperature changes, or material properties. Therefore, fits and tolerances are a practical prerequisite for functional and economical manufacturing processes.

A tolerance defines the permissible deviation range of a dimension from its nominal value. It specifies the limits within which a component may deviate from the ideal geometry without losing its function. Tolerances thus ensure the manufacturability and interchangeability of components, while also influencing manufacturing effort and costs.

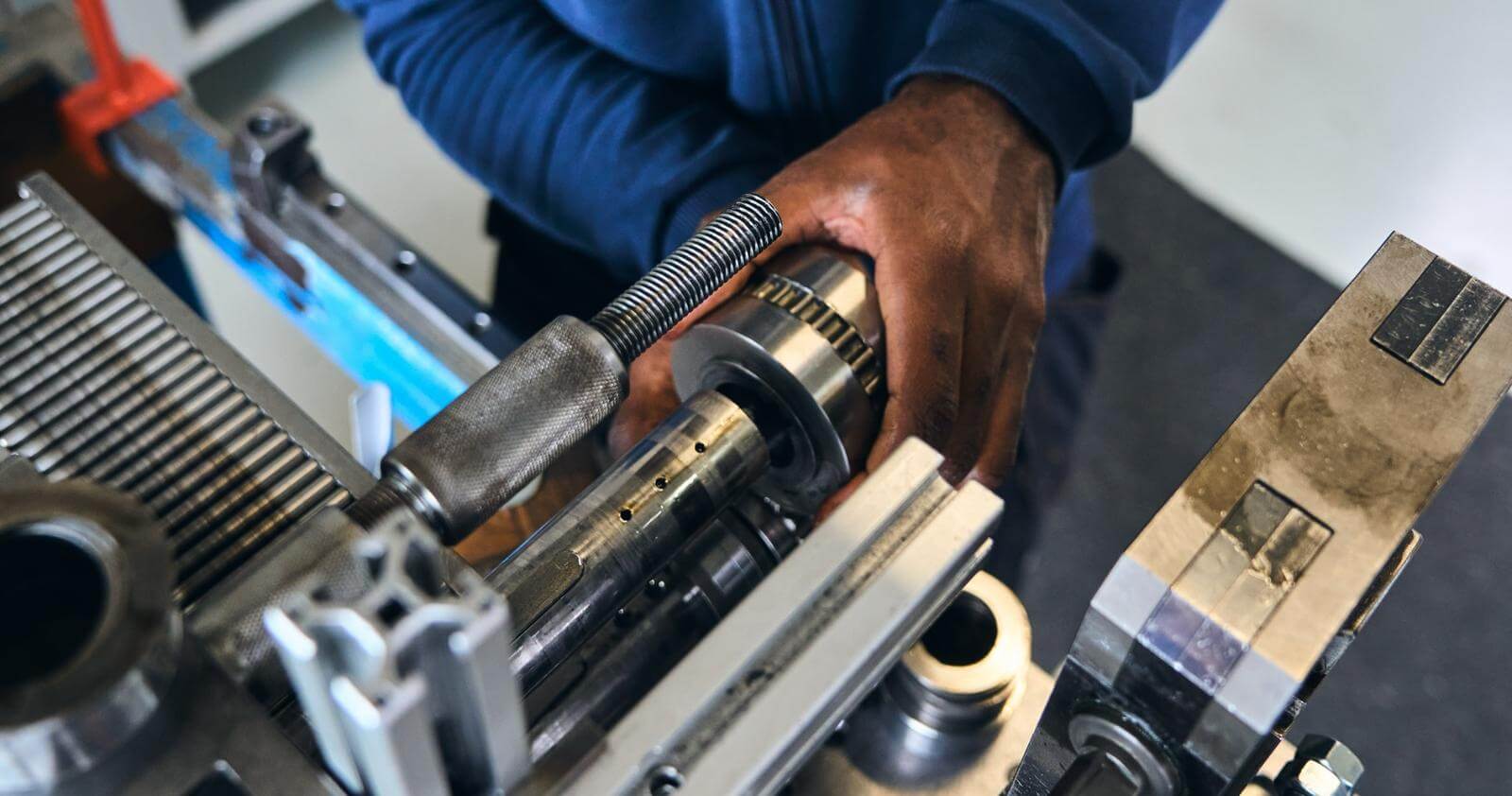

Fits occur wherever components are joined, typically in shaft-hub connections. They result from the interplay of the respective tolerances and determine whether components are movable, backlash-free, or rigidly connected. Thus, fits influence not only assembly but also concentricity, noise behavior, wear, and the service life of an assembly.

Where Conventional Solutions Reach Their Limits

Traditional shaft-hub connections, such as press fits or keyways, function reliably as long as the boundary conditions are precisely met. In practice, however, even minor deviations in diameter, roundness, or coaxiality lead to assembly problems or uneven load distribution. This can result in increased stresses, vibrations, noise, or premature wear. Additional challenges arise from thermal influences, especially when combining different materials. To avoid negative effects, tolerances are often designed very tightly – with correspondingly high manufacturing effort. Especially in series production or under changing operating conditions, it becomes clear that mere dimensional accuracy alone does not represent a robust solution.

How Tolerance Sleeves Close This Gap

Tolerance sleeves address this issue. They are an intelligent connecting element between components that specifically compensates for dimensional deviations. The waves flex flexibly and act like compression springs. The result is a uniform, friction-locked connection. Dimensional deviations within the permissible manufacturing tolerances thus lose their critical character. At the same time, uniform load transmission is created, which reduces vibrations and dampens noise. Thermal expansions of different materials can also be compensated without the connection losing its function. Furthermore, assembly is simplified, as classic methods such as pressing and gluing can be avoided, and less tight tolerances on the shaft and bore are required.

Fits and Tolerances in Practice: Typical Application Examples

The relevance of the interplay between fit, tolerance, and connecting element becomes particularly clear in real-world applications. A classic example is the mounting of bearings in housings. With a conventional press fit, even a small deviation in the bore diameter can lead to the bearing being either too loose or requiring significant assembly effort to install. In addition, with temperature changes – for example, during continuous operation of electric motors – the holding force changes significantly. If a tolerance sleeve is used instead, it can compensate for dimensional deviations while ensuring a uniform, circumferential contact pressure. The bearing remains stably positioned without requiring extremely tight manufacturing tolerances.

Another typical application area is shaft-hub connections for torque transmission, such as in gears, pulleys, or rotors. While classic solutions like keyways or press fits transmit high torques, they are sensitive to series variations or misalignment errors. In practice, this often leads to noise, vibrations, or uneven wear. Tolerance sleeves enable a friction-locked connection where the torque is evenly distributed via the elastic structure. At the same time, assembly and disassembly are simplified, which is a particular advantage for maintenance or service cases.

The strengths of this principle are also evident when combining different materials. For example, if a steel shaft is mounted in an aluminum housing, both components react differently to temperature changes. While a rigid press fit either loses holding force or leads to high stresses, a tolerance sleeve can elastically compensate for these changes in length and diameter. The connection remains functionally stable, even under changing operating conditions.

From Purely Dimension-Based Solutions to Greater Robustness

Fits and tolerances are indispensable foundations of any industrial manufacturing. In practice, however, purely dimension-based solutions reach their limits when series variations, thermal influences, or dynamic loads are added.

Tolerance sleeves expand the classic understanding of fits by accommodating dimensional deviations while enabling secure, friction-locked connections. The focus thus shifts from maximum dimensional accuracy to robust function in real operation – with higher process reliability and reduced manufacturing effort.