Compact power packs: Miniature guides set new standards

In modern designs, engineers and developers are increasingly faced with the challenge of implementing precise linear movements in the smallest of spaces while moving heavy loads. Components such as miniature guides and telescopic spindles offer efficient and space-saving solutions for this.

Thanks to advanced manufacturing technologies and optimized material selection, motion tasks that were considered technically unfeasible just a few years ago can now be implemented.

Miniature guides: Precision and load-bearing capacity in the smallest format

Miniature guides are specifically designed for applications with limited installation space. They are characterized by compact dimensions with high load-bearing capacity and rigidity. Depending on the design, dynamic loads of several hundred kilograms per carriage can be achieved with a guide cross-section of just a few millimeters. This makes miniature guides ideal for applications such as

- Mobile applications (e.g. commercial vehicle technology, side wall and loading equipment)

- Medical technology (e.g. laboratory equipment, imaging devices)

- Automation systems and robotics

- Optical systems and precision machines

The wide range of low-rust or corrosion-resistant variants available today is particularly advantageous, enabling use even under demanding environmental conditions.

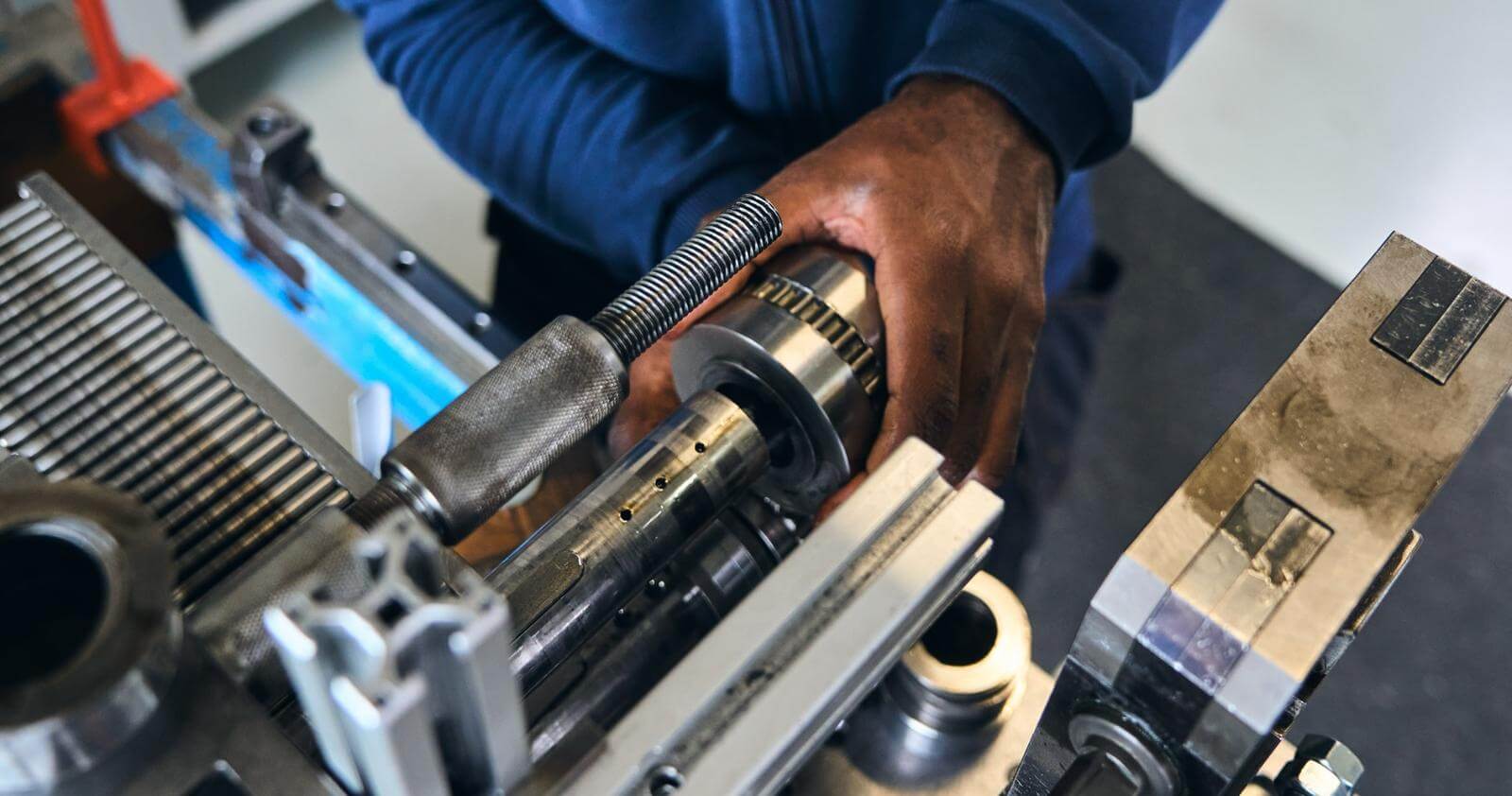

Ball screws: High efficiency for individual requirements

Ball screws are the preferred drive element for high-precision linear movements with high efficiency. Thanks to the possibility of individually adapting the pitch, spindle diameter and nut design, ball screws can be precisely adapted to the respective application.

Typical applications can be found in the following industries:

- Special machine construction

- Medical technology and diagnostics

- Packaging and conveyor technology

- Measurement and testing technology

- Electromobility.

Current trends show that the demands on dynamics, load-bearing capacity and compactness continue to rise in many applications. Manufacturers are responding with new material combinations, improved profile geometries and optimized manufacturing processes to further increase the power density of the ball screws.

Telescopic spindles: Maximum strokes with minimum installation space

Telescopic spindles enable large strokes in a confined space by using several interlocking spindle stages. This allows extremely compact assemblies to be realized, which can be extended to many times their installation length if required. In combination with suitable system components (such as bearing units, shaft couplings, rail guides or nut housings), modular linear systems can be configured for highly specialized applications. Areas of application include:

- Special machine construction and industrial automation

- Lifting systems in vehicles

- Medical devices

- Precision applications in optics and metrology.

Miniature guides, ball screws and telescopic spindles offer engineers enormous design freedom for linear movements in confined spaces. Continuous technical developments – for example with regard to load-bearing capacity, friction optimization, corrosion protection and long-term stability – are opening up new fields of application for these components. This gives designers the opportunity to develop more compact, lighter and at the same time more powerful machines and systems.

Technical support and tailor-made solutions

If you are looking for suitable linear components for demanding applications, we will be happy to advise you and offer a large selection of tried-and-tested solutions. Our extensive range of miniature guides, ball screws and telescopic spindles is complemented by suitable system components and custom-made products. Our team supports you from selection and design to delivery with technical know-how and a high level of solution expertise.

Please feel free to contact us: info@tretter.ch.