Crucial: The calculation and design of tolerance sleeves

In industrial manufacturing, the choice of the right connection technology plays a crucial role – not only technically, but also economically. Assembly times, machining costs and flexibility have a direct impact on overall efficiency. While adhesive bonds or interference fits are still used in many areas, tolerance sleeves offer a cost-effective and efficient connection technology.

Classic connection technologies in comparison

Adhesive bonding is frequently used to securely join components together. However, the process requires waiting times for curing and additional post-processing steps. In addition, temperature or aging influences can negatively affect the service life.

Interference fits are compelling due to their high strength, but involve high machining effort. Tight tolerances must be maintained, which requires precise manufacturing steps. This leads to longer processing times and higher costs, and increases the risk of rejects.

Tolerance sleeves as a cost-efficient alternative

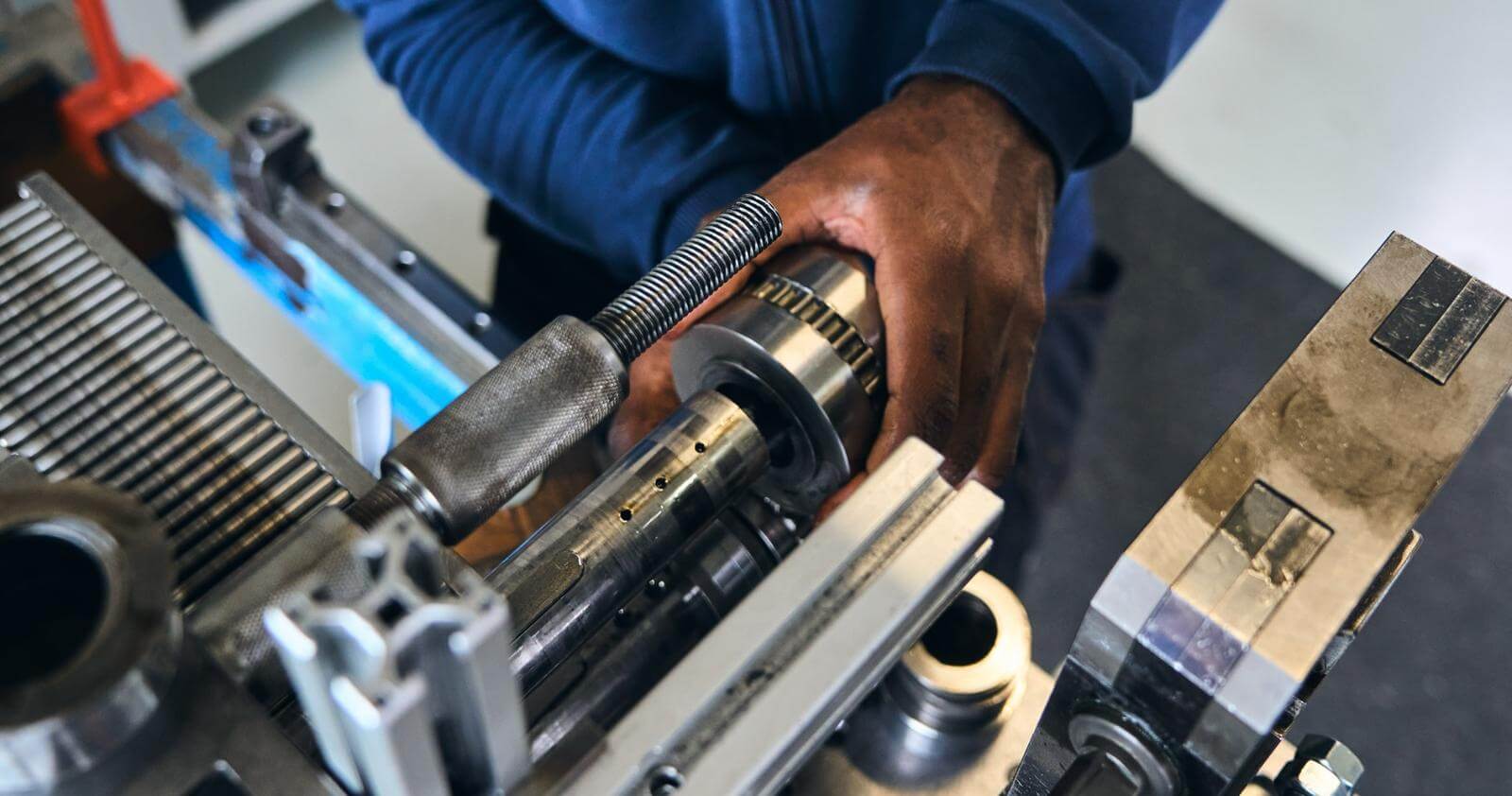

A tolerance sleeve is a thin-walled, corrugated metal band in cylindrical form. Due to their elastic corrugations, a springy effect is created during pressing: the sleeves press evenly between the shaft and the hub and ensure a non-positive connection. This allows even larger manufacturing tolerances, misalignment or thermal expansion to be reliably compensated.

This simple but effective mechanism makes assembly much faster and more straightforward than with adhesive bonding or interference fits. Adhesives do not have to cure, and precise reworking is not required.

The advantages at a glance:

- Fast assembly: no gluing, no waiting times

- Reduce assembly costs: larger manufacturing tolerances are permitted

- Reduce machining costs: less complex reworking required

- Flexibility: Connection can be detached and reused

- Protection function: Use as a slip clutch in case of overload

What does this look like in practice?

In a direct comparison, tolerance sleeves show clear cost advantages over adhesive bonding and interference fits.

An application example: 3 timing belt pulleys are to be attached to a shaft with 08 mm. A 12 mm long and 3 mm wide feather key was selected as the parallel key, which can transmit 5.8 Nm. A comparable tolerance sleeve can transmit 5.7 Nm. With the tolerance sleeve solution, you save around 38% of the costs.

In electric motors, the pressing in of a tolerance sleeve is sufficient instead of glued stators. This considerably reduces the assembly time.

When mounting rolling bearings, tolerance sleeves allow for larger tolerances in bores and shafts, which reduces the manufacturing effort.

In applications with thermal expansion, the elastic properties of the tolerance sleeve reliably compensate for the expansion and thus reduce rejects.

Tolerance sleeves are more than just connecting elements – they are efficient problem solvers that save time and significantly reduce assembly costs. As an alternative to adhesive bonding and interference fits, they offer engineers and designers the opportunity to reduce machining costs while at the same time obtaining a reliable connection solution.

We will advise you on the selection and design of the right tolerance sleeve and support you from the idea to the finished component. Please feel free to contact us