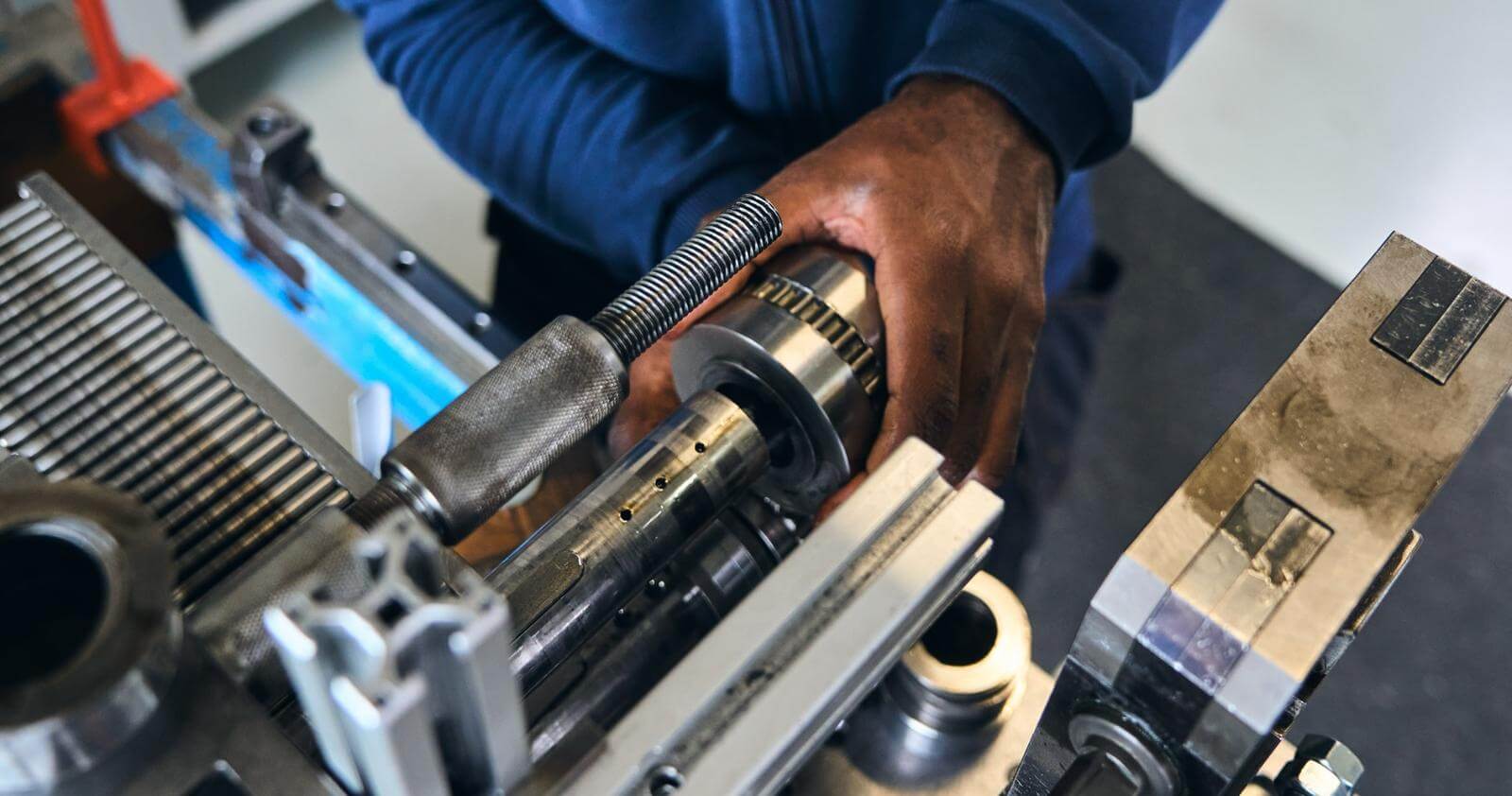

More precision in less space: Torque ball bushings in use

In modern automation technology, space is often limited – but there is all the more demand for movement. Designers, engineers and technicians face the daily challenge of developing powerful and compact solutions for linear guides. Torque ball bushings – also known as spline shaft guides – offer an equally clever and efficient answer to this.

These special round guides not only enable precise linear movement, but also transmit torques at the same time – and all this with a small installation space. Thanks to their torsion-proof design, they often even replace two parallel shaft guides. This article will show how this works and what practical advantages this offers.

What makes torque ball bushings so special?

Compared to classic ball bushing guides, torque shafts have two or four axially parallel guide grooves. This so-called spline shaft enables play-free, precise and resilient guidance – very similar to a profile rail guide. At the same time, the design and installation remain as simple as with a round guide.

The contact of the balls in the raceways of the bushing and shaft makes it possible to absorb significantly higher loads and torques. The result: A durable, smooth-running and compact guide solution that also masters shock loads with ease. Particularly advantageous: A hollow shaft not only saves weight, but can also be used for media routing – for example for compressed air, coolant or electrical cables.

Typical areas of application

Torque ball bushings are true all-rounders – and are in demand wherever compact design, high precision and reliable power transmission are required. In practice, they are used in the following applications, for example:

- Packaging and transfer systems

- Format adjustments in cutting units and conveyor belts

- Synchronous shafts in machine tools

- Brush deburring systems with contact pressure regulation

- Assembly machines with rotary indexing systems

- Testing and coating systems

- Suction grippers with fine positioning

The advantages at a glance

- Compact, lightweight design

- Torsion-proof single-shaft linear guide replaces two guides

- Hollow shaft option saves weight and creates space, for example for compressed air or cooling and lubricating fluids

- High torques, load ratings and service life

- Play-free, smooth movement – even under load

- Three preload classes (without, light, medium)

- Avoidance of the stick-slip effect at low speeds

- Insensitive to dirt thanks to wipers

- Optional: low rust

More precision in less space

Whether in packaging technology, special machine construction or in high-precision testing and production systems – torque ball bushings are the right choice wherever compact design, freedom from play and high load capacity are important. By combining round guide and torsion-proof linear guide, both installation space and assembly effort can be significantly reduced.

Our service for you

We not only offer you a wide range of torque shafts and bushings – we also provide you with individual advice on the selection of the right components for your application. Whether standard solution or customer-specific design: Together we will find the optimal solution for your requirements.

Contact us now: info@tretter.ch – we look forward to your project!