Tolerance Sleeves: Small Efficiency Boosters in the Automotive Industry

Stator Fixation

A secure and stable attachment of the stator to reduce vibrations and oscillations is crucial for the efficiency and service life of the machine. Stator fixation refers to the attachment of the stator in electrical machines, such as electric motors or generators. The stationary stator encloses the rotor. The stator can be fixed in the drive motor with the aid of a tolerance sleeve. Tolerance sleeves greatly simplify assembly. Compared to alternative bonding, there is no hardening time for the adhesive and no post-processing of the stator. In addition, tolerance sleeves allow for larger tolerances in the housing and on the stator and compensate for the thermal expansion of different materials. This fastening technology is frequently used in the automotive industry, especially in electric vehicles and hybrid drives, to maximize the efficiency and reliability of the electric drive systems.

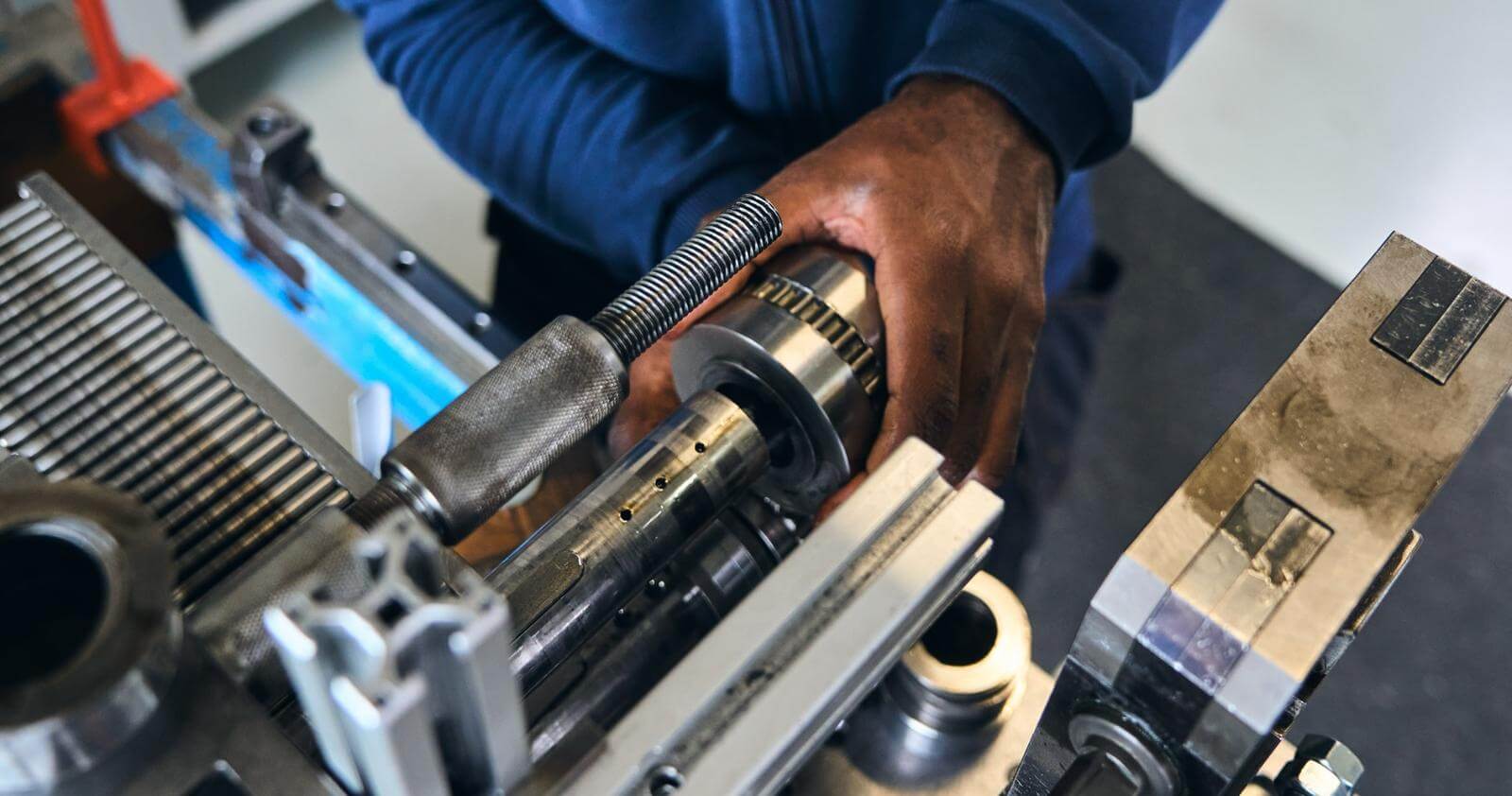

Rolling Bearing Assembly

Vehicles with combustion engines rely heavily on rolling bearings to ensure that various vehicle systems and components such as engines, transmissions, differentials, steering systems, braking systems, wheel suspensions and other vehicle components function properly. Here, too, tolerance sleeves ensure a tight fit and positively influence the performance of the rolling bearing.

Torque Transmission/Slip Clutch

A slip clutch (also called an overload clutch) has the task of preventing an overload. It slips and separates the connection between the drive and output sides when the transmitted torque exceeds a defined safety value. This protects the machine and drive from damage. Tolerance sleeves can be used as a slip clutch for mechanical overload protection and to limit the maximum torque. The tolerance sleeve ensures that the clutch slips in the event of an overload, instead of damaging the components, and serves as a protection mechanism for the entire drive train. The torque at which the slip clutch is triggered can be adjusted by the specification and design of the tolerance ring to meet different requirements.

This effect is also of interest in the steering system of a vehicle as theft protection. When attempting to crack the lock with a powerful jerk on the steering wheel, the steering spindle slips through and the locking bolt is not damaged.

Further Applications

When a defined power transmission plays a crucial role, tolerance sleeves are also used in drive technology in belt pulleys, flywheels or gears. In fans, tolerance rings ensure a secure connection between the fan wheel and the motor.

Tolerance sleeves are secure, non-positive connections that save costs in the machining of the attachments and can be quickly and easily assembled and disassembled. We have compiled the most important information here.

We will assist you in developing a suitable connection solution from the design and test phase to the finished component. Please feel free to contact us at: info@tretter.ch.

We look forward to your inquiry!