Precision in motion: Connection solutions for robotics

Robotics is one of the most innovative fields in modern mechanical engineering. Robots have become indispensable in modern manufacturing and automation processes. They now perform a variety of tasks: welding, assembling, gripping, sorting, or packaging – often at breakneck speed, with the highest precision, and under constant stress. Each individual movement must be executed precisely, as even the smallest deviations can disrupt the entire process.

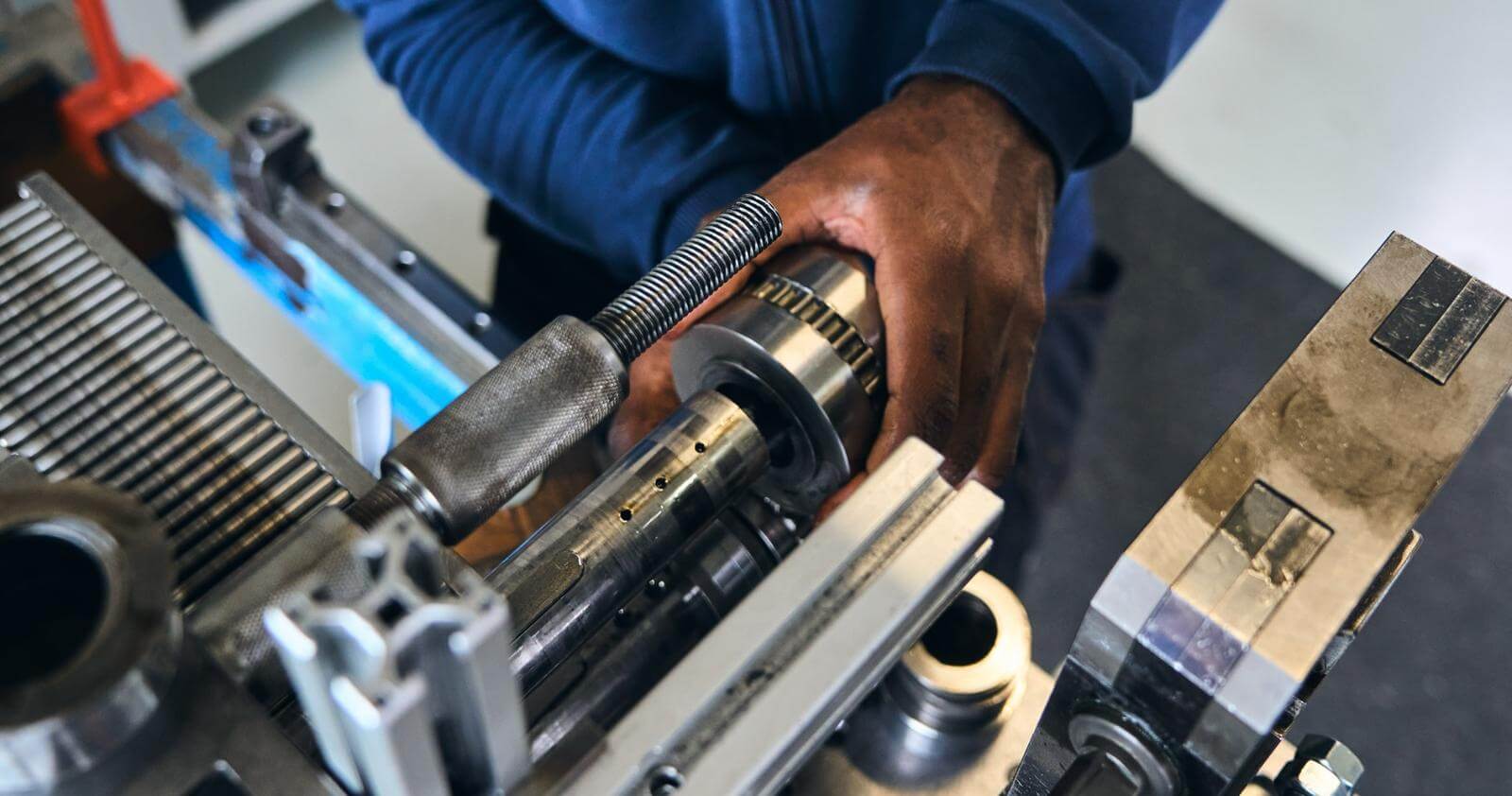

For robots to perform their work reliably and consistently, components are required that work just as precisely as the robots themselves. While tolerance sleeves ensure a secure, compact, and flexible connection, linear guides guarantee precise, play-free movement along an axis.

Dr. TRETTER offers customized solutions that can be adapted to any application – from compact cobots to complex industrial robots.

Tolerance sleeves: The invisible helpers in robot arms

A robot arm can perform numerous movements simultaneously: rotary movements at the wrist, swivel movements at the shoulder, or gripping movements at the hand. Each axis must be precisely aligned and transmit torque reliably. Tolerance sleeves perform central functions here.

Torque transmission: When attaching motors to robot axes, tolerance sleeves are used to transmit torque from the motor to the axis in a non-positive manner. This allows drives to be integrated compactly and efficiently into the joints without the need for additional, large fastening solutions.

Compensation of tolerances: Especially in highly complex robot structures, components often have to be made of different materials. Due to different thermal expansions, fits can become inaccurate. Tolerance sleeves flexibly compensate for these differences, ensuring a durable and reliable connection.

Vibration and noise damping: Tolerance sleeves have a spring-elastic effect. They dampen vibrations and reduce noise. This is particularly important in collaborative robots (cobots) that work directly with humans.

Tolerance sleeves thus offer numerous advantages:

- Compact design: The use of tolerance sleeves enables space-saving and lighter designs to be realized.

- Cost and time savings: Complex mechanical processing, bonding processes, or keys are eliminated. Assembly is quick and easy.

- Compensation of manufacturing tolerances: Larger tolerances in components are possible without impairing the function.

- Vibration and noise reduction: Vibrations are reduced by the spring-elastic effect, which leads to a longer service life and smoother running.

- High flexibility: Tolerance sleeves are suitable for numerous materials and are available in various sizes and designs.

Linear guides: Precision in every movement

In robotics, linear movements also play an important role in addition to rotary movements. Linear units and linear guides position grippers, tools, or sensors with millimeter precision. Torque ball bushings, also known as spline shaft guides, enable particularly play-free and torsion-proof linear movement. They are compact and take over both the guidance and the torque transmission in a single component. This saves installation space and weight – a significant advantage in modern robot systems. For example, suction grippers in packaging robots can be moved linearly at the same time and positioned in a torsion-proof manner. In pick-and-place systems, components must be picked up and placed with millimeter precision. Linear guides enable play-free and low-friction movements even at high cycle rates.

Together to the optimal robotics solution

Whether in collaborative robots (cobots), industrial robots, automated handling systems or special machines: Tolerance sleeves and linear guides from Dr. TRETTER help ensure that robots work precisely and reliably even under high loads. They are available in various sizes and designs and can be individually adapted to the respective requirements. As an experienced partner, we accompany you from selection and design to the manufacture and integration of your individual solution. Please contact us: info@tretter.ch.

We look forward to your project!