Tolerance sleeves: True all-rounders in logistics

In the logistics industry – from automated conveyor systems to modern sorting and packaging lines – efficiency, precision and reliability are essential. At the same time, it is subject to high mechanical loads, fluctuating temperatures and, in some cases, large manufacturing tolerances.

Tolerance sleeves are very useful here. These connecting elements enable non-positive, elastic connections, compensate for manufacturing tolerances, dampen vibrations, and simplify assembly. This saves time and costs—and increases the reliability of logistics systems.

Typical areas of application for tolerance sleeves in logistics

Driven conveyor rollers: flexible assembly, precise operation

In storage and distribution systems, conveyor rollers must be positioned precisely. Instead of welding and/or gluing them in place at great expense, they are positively connected to the shaft using a tolerance sleeve. This allows for subsequent adjustment, for example for the integration of sensors. At the same time, temperature differences and material expansions are compensated for.

Connection solution for screw conveyors – without any weld seam

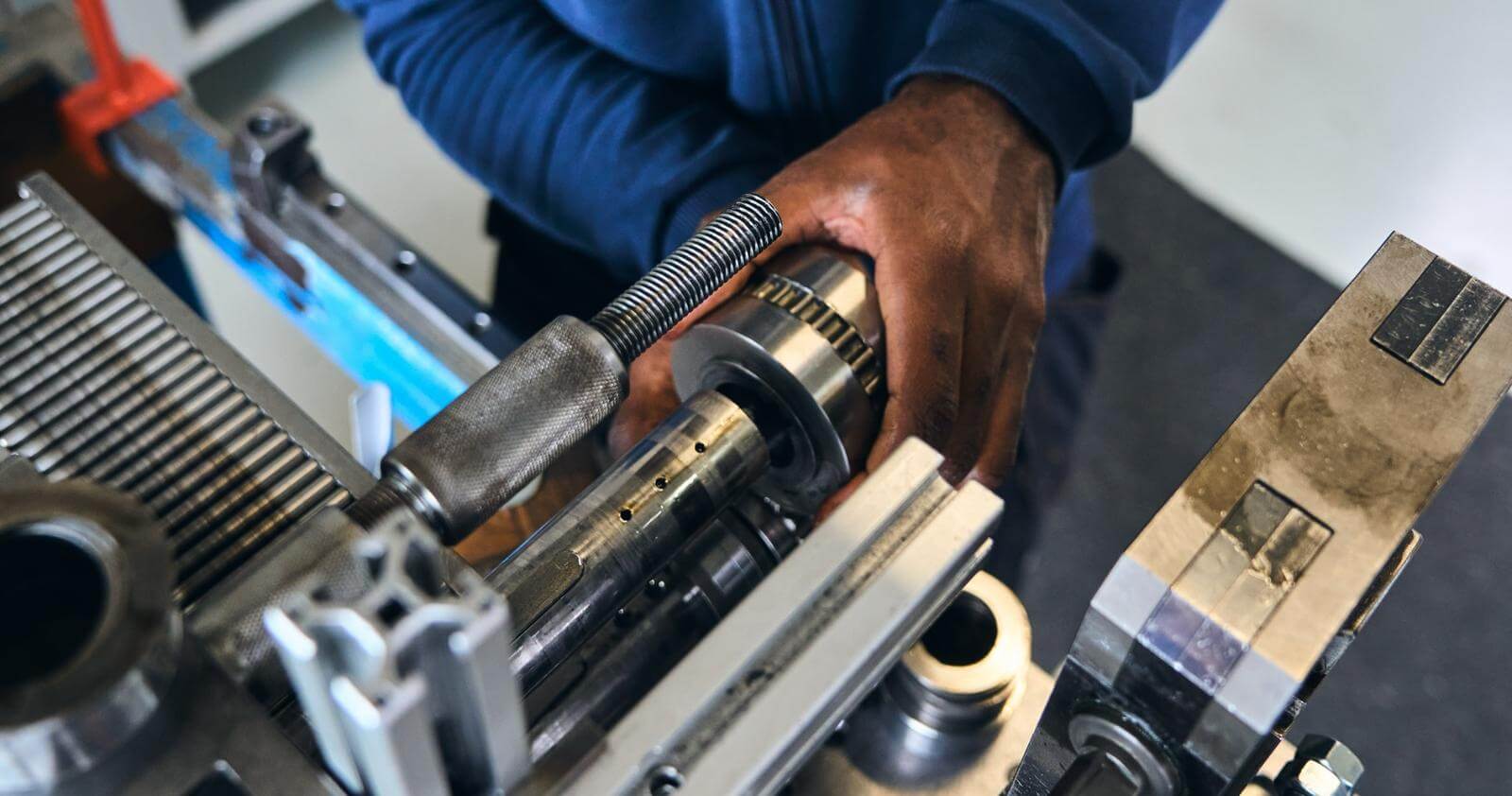

A customer from the intralogistics sector was looking for an alternative to the welded connection for a screw conveyor. The solution was a precisely fitting tolerance sleeve that was integrated into the motor – with the following advantages: lower risk of breakage, reusable components and reduced manufacturing costs.

Tolerance sleeves in order picking and packaging

Pick-and-place systems, palletizers or automatic labeling systems benefit from precise movement. Here, tolerance sleeves ensure secure bearing fastening or reliable torque transmission to drive components. The result: fewer downtimes and greater process stability.

Tolerance sleeves can also be used in a variety of ways and to good effect in lifting and hoisting systems, automated storage systems, rotary tables, swivel units, baggage conveyor systems and in refrigerated and deep-freeze logistics.

The advantages of tolerance sleeves at a glance

- Fast, tool-free assembly – ideal for high throughput

- Compensation of tolerances and thermal expansion

- Vibration and noise damping

- Easy disassembly for maintenance or conversion

- Can be combined with steel, aluminum, plastic

- Suitable for individual and series production in the logistics industry

Whether automated conveyor systems and storage processes, screw conveyors or packaging: tolerance sleeves are a clever connection solution for demanding conditions and therefore a real added value for logistics. They increase the efficiency of the systems, improve the service life of the components and ensure smooth processes.

We support you from the technical design to series implementation – quickly, pragmatically and solution-oriented. Our «Swiss made» tolerance sleeves are available at short notice and also available as custom-made products on request. We will find the right solution for your needs!

Please do not hesitate to contact us without obligation at info@tretter.ch. You can also find a lot of information on our website tretter.ch